What We Learned About Hemp Building Products

In an ever-evolving green building industry, our team at Green Building Alliance attempts to keep our members aware of all the choices at their disposal when it comes to designing, building, and operating healthier and higher performing buildings.

In an ever-evolving green building industry, our team at Green Building Alliance attempts to keep our members aware of all the choices at their disposal when it comes to designing, building, and operating healthier and higher performing buildings.

The most complex choices are often made around building products, given the mind-boggling number of attributes of the products that go into our buildings, the variety of labels and certifications that vet them, and the lack of available information about health and sustainability of many products. Trade-offs and hard decisions are often accepted as the norm.

But there are some solutions on the horizon that appear to minimize trade-offs and maximize benefits – and these are worth a serious look. One such solution is hemp.

GBA never promotes one specific product or solution over another, as every project is different and requires customized strategies – however, we are incredibly intrigued by hemp and the opportunities it could offer our industry, and we wanted to ensure it was solidly on our network’s radar.

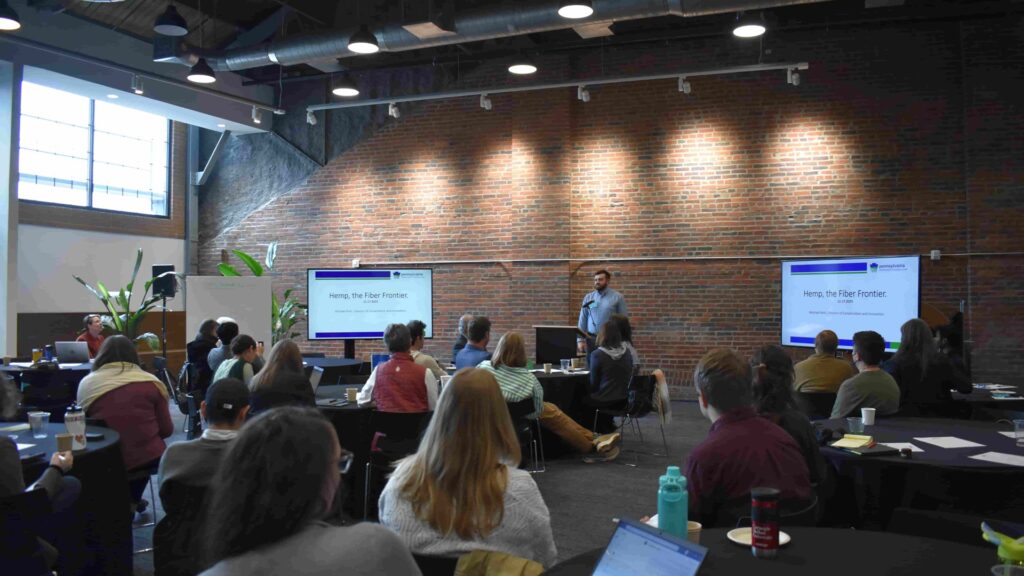

So, in the fall of 2023, more than 60 people gathered with GBA at the Roundhouse to learn about the green building potential of hemp: people representing construction, design, consulting, engineering, ownership, and more. Thanks to a grant from the Pennsylvania Department of Agriculture (PDA), we had the opportunity to learn from half a dozen of our region’s experts in hemp production, industry, construction, and research.

The presenters who shared their expertise with us are well-respected throughout the industry and many of them are leading innovation happening both in Pennsylvania and around the country.

Lori Daytner is a board member of the Pennsylvania Hemp Industry Council. Lori is a passionate advocate for hemp, having worked with farmers in western Pennsylvania to grow hemp for fiber and spearheading a hemp construction project that helped inform the industry as a game-changing case study in residential hemp application.

Cameron McIntosh from Americhanvre is widely seen as an industry expert with hemp insights from the U.S. and abroad. He acts as a consultant, builder, and educator. Cameron and his team are full-service hemp building material installers and have worked on projects across the country. Among other things, they have perfected a spray-applied methodology for hempcrete.

Dr. Ali Memari is the director of the Pennsylvania Housing Research Center at Penn State University and has published several scholarly articles on hemp’s performance as a building material. Dr. Memari also serves as faculty in Penn State’s civil engineering, construction, and architectural engineering departments, giving him a deep understanding of how this product could fit into the industry.

Michael Roth serves as the Director of Conservation and Innovation at the Pennsylvania Department of Agriculture. Michael’s work includes many topics, but his main focus areas include sustainability, biomaterials, and agricultural technology. Michael’s enthusiasm for hemp includes its triple-bottom-line benefits and its potential to improve the economic vitality of our region.

Together, Ana Konopitskaya and Drew Oberholtzer operate Coexist Build, a full-service architecture firm and manufacturer focused on healthy building, and Lunaria Farm, a 10-acre regenerative organic research farm that serves as their innovation and product development facility. Among other product innovations, they created insulating Hemp Block, bio-compostable hemp-based plastic, and a DIY kit for a small cabin designed to incorporate hemp-based building materials. Ana is a licensed architect and WELL accredited professional. Drew is an Emmy awarded media professional whose work includes National Geographic and Animal Planet.

Alison Mears and Jonsara Ruth are co-founders of the Healthy Materials Lab at the Parsons New School of Design. Their lab creates resources, educational programming, and prototypical innovative housing models for a new post-petroleum world. Their research includes investigating how hemp building materials compare to other products in terms of their impact on human health. Together, Alison and Jonsara were awarded the 2022 Women in Architecture Innovation Award from Architectural Record.

Here are just a few of the things we learned at the workshop.

Hemp is a Hard-Working Crop

According to Lori Daytner from the Pennsylvania Hemp Industry Council, hemp is one of the most versatile crops in the world. It can be used as a rotation crop and heals soil. Industrial hemp is planted similarly to other common commodity crops like corn and soy and can be harvested with existing (slightly modified) equipment.

In 2018, the Farm Bill authorized the production of hemp and removed hemp and hemp seeds from the Drug Enforcement Administration’s (DEA) schedule of Controlled Substances. This gave farmers in Pennsylvania the chance to start growing hemp as a crop. Hemp can be used for paper and packaging, textiles and apparel, biomass feedstock, animal bedding, fiber composites, bioplastics, flooring, insulation, mulch, compost, and more. Other market opportunities for hemp include those in the auto market, the green building industry, and consumer goods and food.

Hemp Can be a Tool for Economic Development and Bridging the Urban-Rural Divide

According to Michael Roth, the PDA sees hemp as an opportunity for farmers to diversify their revenue, especially those who are running small to mid-sized farms. PDA sees real value in the triple bottom line offered by hemp – its benefits to human and animal health, climate, and economic development. Hemp’s sustainable and non-toxic nature makes it a viable alternative to more toxic products. It encompasses the entire spectrum of workforce opportunities, with the potential to grow jobs across the pipeline from laborers to researchers. And it can provide a clear and local supply chain, offering the opportunity to develop a regional product that can support local communities. Benefits of this crop could be experienced in rural and urban communities alike.

Hemp is Worth a Look as a Green Building Product

Our hemp workshop focused mostly on hempcrete (also known as hemplime) as a green building product. Hempcrete is a non-structural, bio-composite insulation and walling material. It is made up of the inner woody core of the fiber industrial hemp stalk combined with a lime-based binder and water. As Cameron McIntosh said in his presentation, “hemp and lime have been friends for hundreds of years.”

Hemp building products have been widely used – and are approved for commercial and residential use – in the U.K. and France – and have now been approved for residential use in the United States. Hempcrete, which is fire resistant (presenters reminded the audience that it is not fireproof) and non-toxic, can be applied to projects in three ways: cast-in-situ, spray applied, or pre-cast. While applications in the U.S. are primarily residential so far, there is potential for commercial construction as well.

The goal of a truly green building product is to support the industry’s main priorities of human health, energy performance, and environmental footprint – to reduce the negative impacts that buildings can have on people and the climate. There are very few products that can serve all these priorities – especially ones that can be found within a few hundred miles of a project (products and materials that are specified near a project site help support the regional economy and reduce the project’s overall carbon footprint).

Hemp offers the possibility of specifying a product that is harvested and manufactured in our region, has a negative carbon impact, and can offer a legitimate alternative to traditional insulation materials to support an efficient building envelope. There are very few products that can do this, and the sustainable construction industry is starting to take notice as hemp’s presence at conferences like Greenbuild has been increasing. In addition to benefits already mentioned, hemp is pest-resistant and when paired with lime (as it is in hempcrete), it is also mold resistant.

Pennsylvania is a Leader in Hemp Research and Innovation

While nearly all our speakers at the workshop are recognized as national leaders and experts on the topic of hemp (they have all presented together in the past), nearly all of them also live and work in Pennsylvania. The combination of research, innovation, and application that is happening in this region came as a surprise to most workshop participants. The fact that this region also boasts an involved and passionate green building industry means that it is the perfect place to put such research and innovation to use in the market.

Pennsylvania is in a unique position to be a leader in hemp products, given its generally high-quality soil, history of farming, strength in research and innovation, and a supportive and innovative Department of Agriculture.

Remaining Questions and Regional Challenges

While hemp has been widely used in commercial and residential projects throughout Europe, one main question audience members came away with following the workshop was: how likely is it that hemp will soon become available for commercial projects?

Given that most of the work done by GBA’s membership is currently in the commercial sector, we will continue to explore this question. One development in this direction that presenters Alison Mears and Jonsara Ruth pointed to is the creation of a commercial guide spec that should be released by the U.S. Hemp Building Association in 2024.

A key challenge to scaling the hemp industry in our state is the lack of a regional decordication facility. Decordication separates hemp fibers through a mechanical process so they can be used for building and other types of products. Currently, while hemp can be grown in Pennsylvania, the absence of a decortication facility means that it cannot be fully processed and manufactured here, thus reducing its benefits as a “regional” product. Further investment is needed for such a facility, and advocates are pursuing this now.

Otherwise, GBA plans to continue following the development of hemp in the green building industry on a regional scale and at the national and international level. A huge thanks to all our speakers, to the PA Department of Agriculture, and to all the workshop participants who brought their questions and commentary to this conversation!

We look forward to learning more with you!

Additional Resources

If you want to learn more about hemp, here are some resources and websites that offer a deeper dive:

- Healthy Materials Lab Hemp + Lime Handbook

- Penn State Housing Research Center Report on Thermal, Energy, and Indoor Environmental Quality Performance of the PA Hemp House

- The Pennsylvania Hemp Industry Council

- Hemp Building Project Highlights from Americhanvre

Many details shared in this blog are direct excerpts from presentations given by Lori Daytner, Michael Roth, Cameron McIntosh, Ana Konopistkaya, Dr. Ali Memari, Jonsara Ruth, and Alison Mears. Thanks again to each of them!